Key Features:

-

Custom Design:

– Tailored to meet specific capacity, material, and operational requirements.

– Options for vertical, horizontal, cylindrical, or rectangular configurations.

-

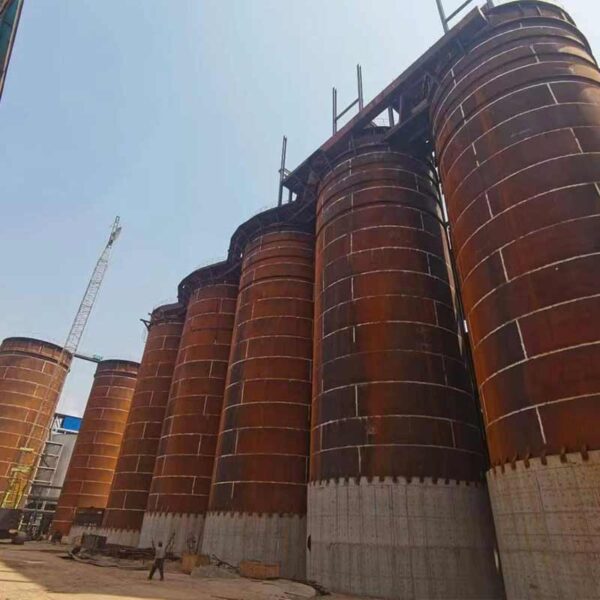

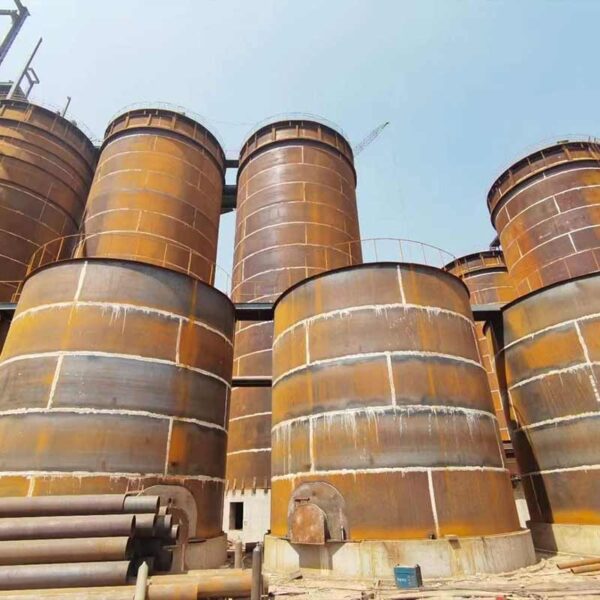

High-Quality Materials:

– Constructed from premium materials such as stainless steel, carbon steel, fiberglass, and polyethylene.

– Resistant to corrosion, extreme temperatures, and chemical exposure.

-

Advanced Safety Features:

– Equipped with pressure relief valves, level indicators, and leak detection systems.

– Complies with international safety standards (e.g., ASME, API, ISO).

-

Efficient Installation:

– Professional installation services, including site preparation, assembly, and testing.

– Ensures proper alignment, stability, and functionality.

-

Durable and Long-Lasting:

– Engineered for long-term performance with minimal maintenance.

– Suitable for both indoor and outdoor applications.

-

Eco-Friendly Options:

– Leak-proof designs to prevent environmental contamination.

– Use of recyclable and sustainable materials.

Customization Options:

-

Material Selection:

– Stainless steel for high corrosion resistance.

– Carbon steel for high strength and durability.

– Fiberglass or polyethylene for chemical resistance and lightweight applications.

-

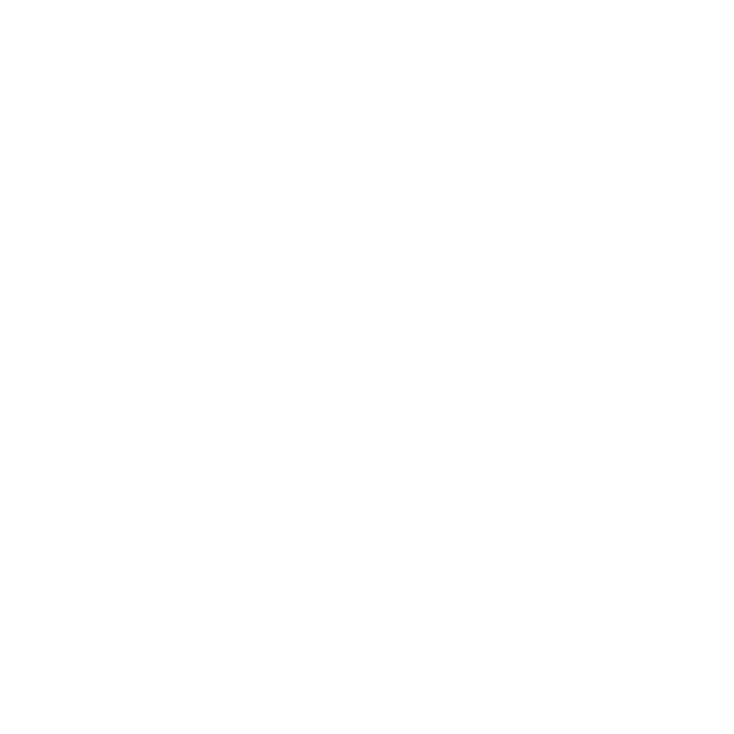

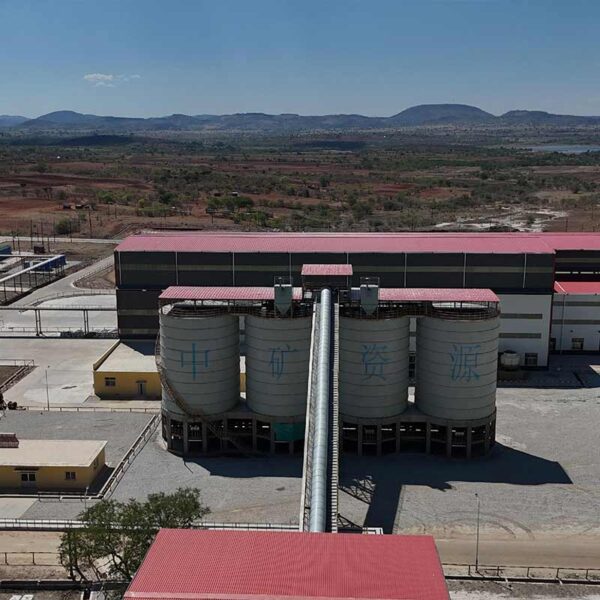

Capacity and Dimensions:

– Customizable sizes, ranging from small-scale (a few hundred liters) to large-scale (millions of liters).

– Designed to fit specific site constraints and operational needs.

-

Special Features:

– Insulation for temperature-sensitive materials.

– Mixing systems, heating/cooling coils, and agitators for process integration.

– Double-wall construction for enhanced safety and leak prevention.

-

Coatings and Linings:

– Anti-corrosion coatings for harsh environments.

– Food-grade linings for industries such as food and beverage or pharmaceuticals.

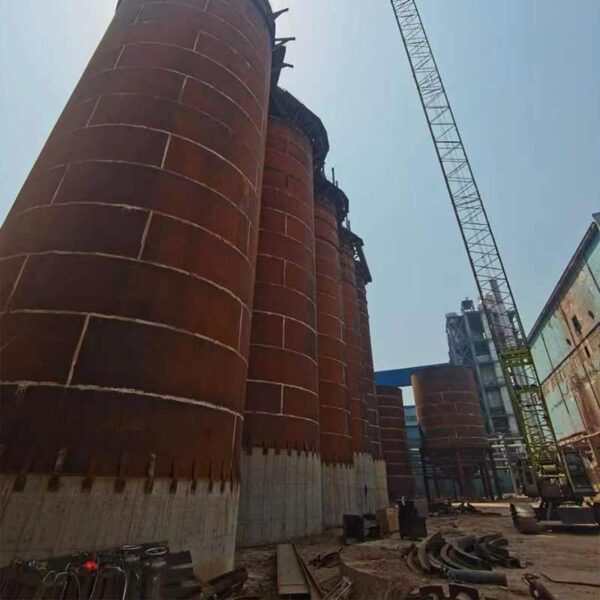

Installation Services:

-

Site Assessment and Preparation:

– Comprehensive site evaluation to ensure optimal tank placement.

– Foundation design and preparation for stability and safety.

-

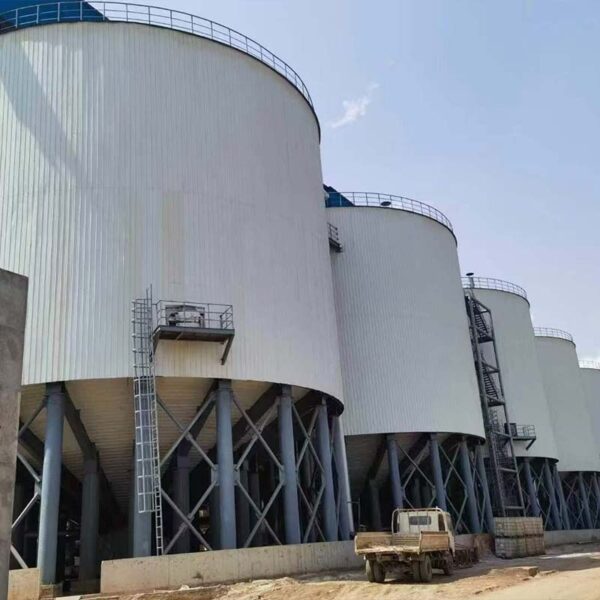

Professional Installation:

– Skilled technicians for precise assembly and alignment.

– Use of advanced equipment and techniques for efficient installation.

-

Testing and Commissioning:

– Hydrostatic testing, pressure testing, and leak detection to ensure tank integrity.

– Final inspection and commissioning for operational readiness.

-

Maintenance and Support:

– Regular inspection and maintenance services to extend tank lifespan.

– Emergency repair and retrofitting services as needed.

Applications:

– Chemical Industry:Storage of acids, alkalis, solvents, and other chemicals.

– Oil and Gas:Storage of crude oil, refined products, and liquefied gases.

– Water Treatment:Potable water storage, wastewater treatment, and rainwater harvesting.

– Food and Beverage:Storage of liquids such as milk, juice, wine, and edible oils.

– Pharmaceuticals:Safe storage of raw materials, solvents, and finished products.

– Agriculture:Storage of fertilizers, pesticides, and irrigation water.

Advantages:

– Tailored Solutions:Custom designs to meet specific project requirements.

– Quality Assurance:High-quality materials and precise installation ensure reliability.

– Safety Compliance:Meets international standards for safety and performance.

– Cost-Effective:Long lifespan and low maintenance reduce operational costs.

– Sustainability:Eco-friendly materials and designs support green initiatives.

Why Choose Our Custom Industrial Storage Tanks and Installation Services?

Our custom industrial storage tanks and installation services are designed to deliver unmatched quality, safety, and efficiency. With a focus on innovation and customer satisfaction, we provide end-to-end solutions that meet the unique needs of your industry. Whether you need a standard tank or a fully customized solution, we are here to help.

Reviews

There are no reviews yet.